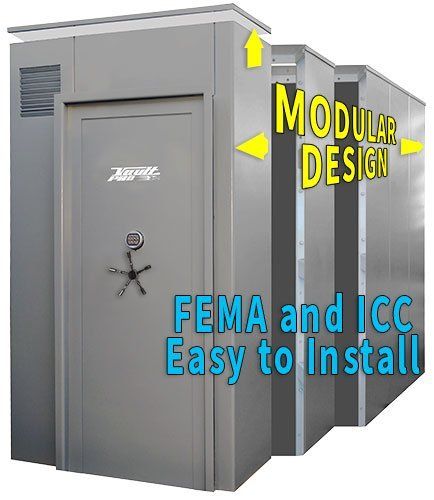

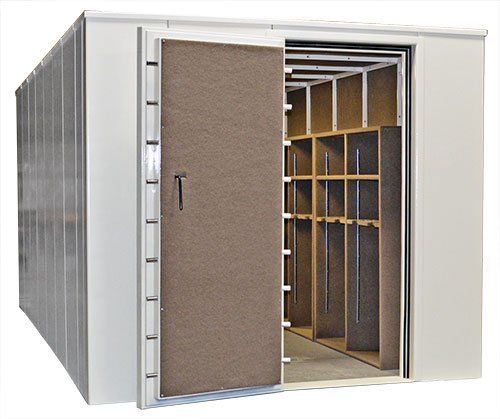

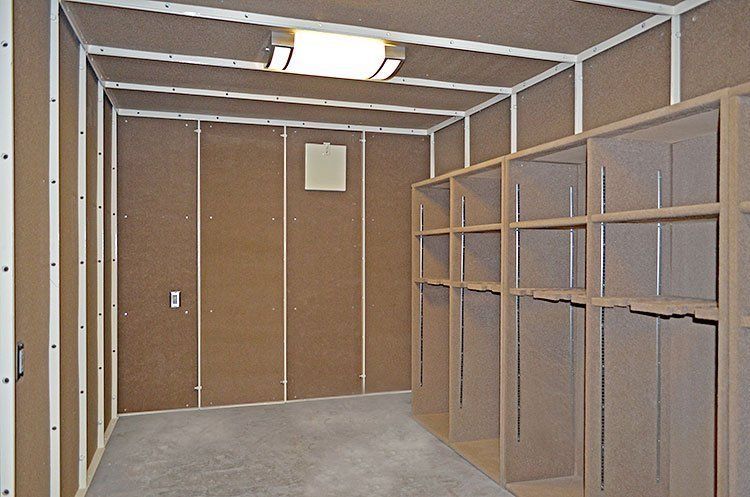

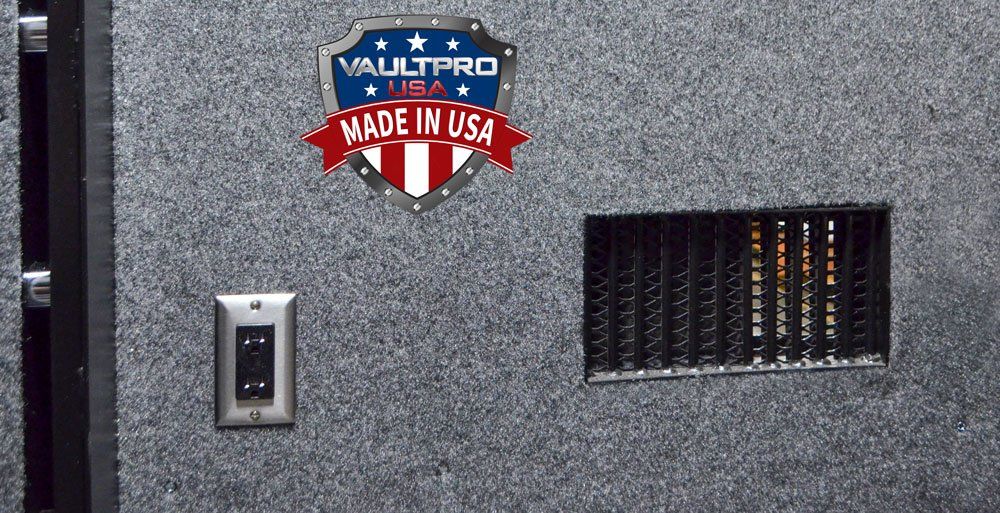

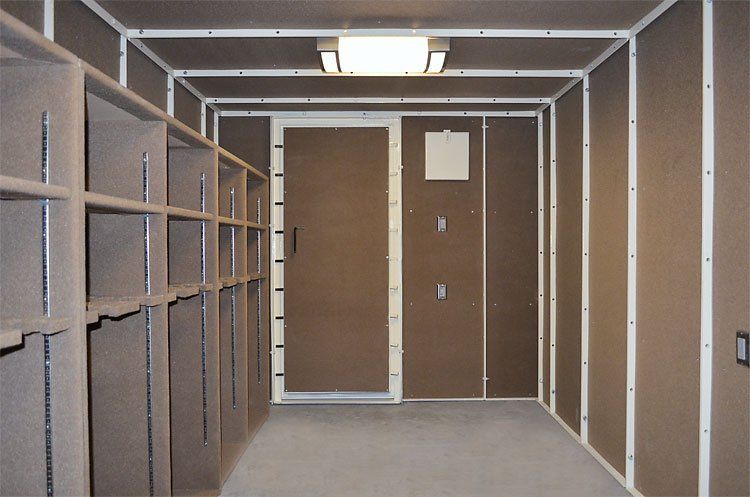

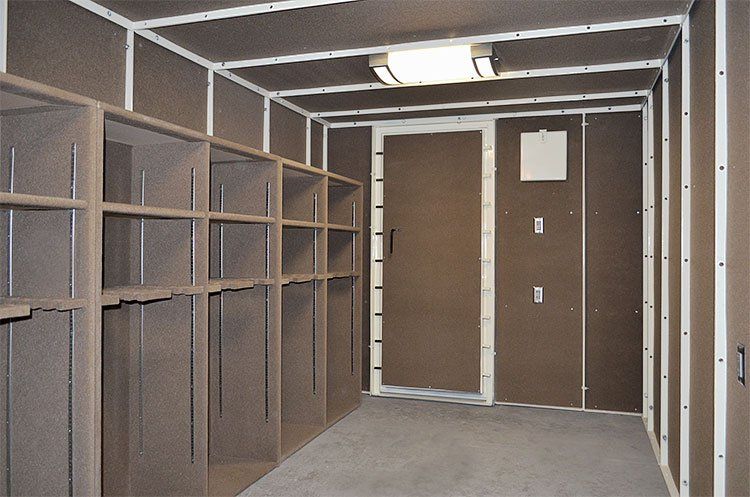

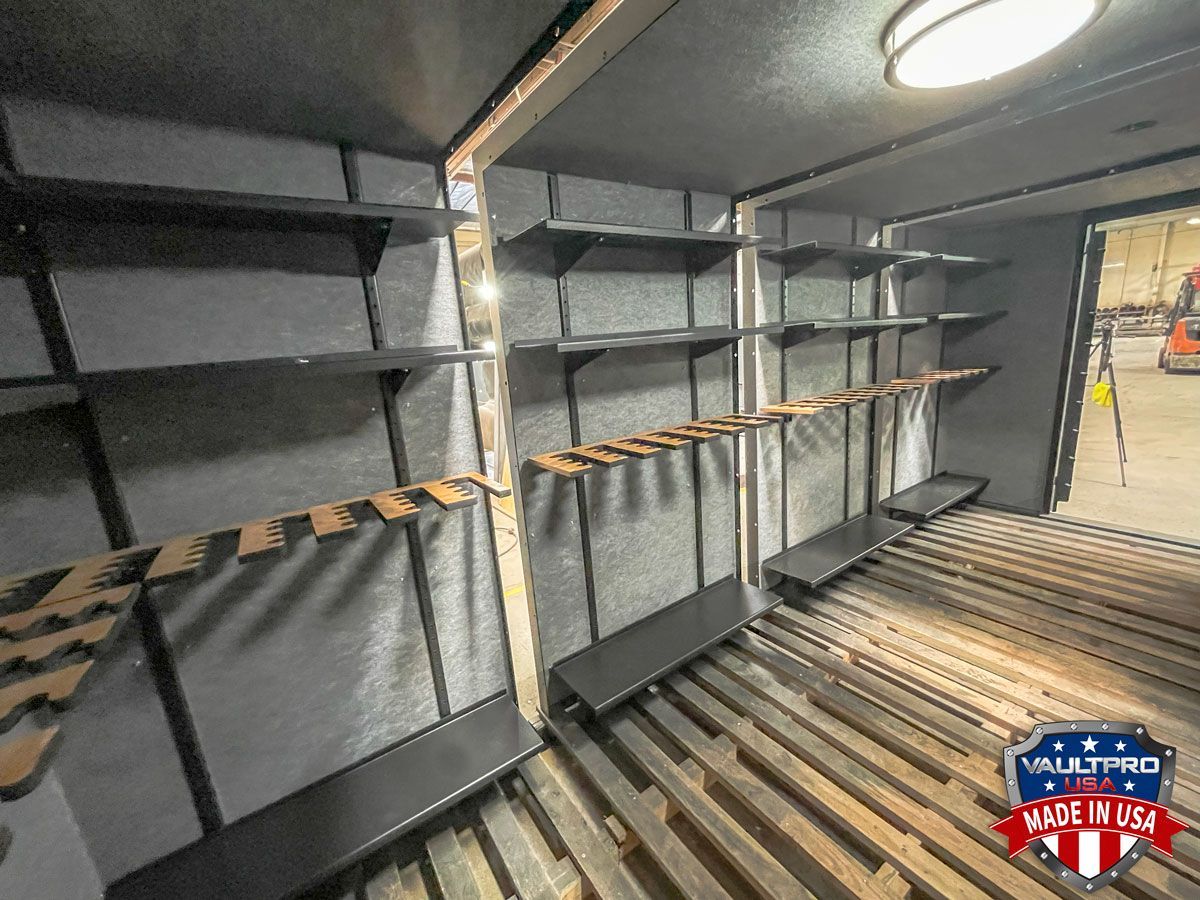

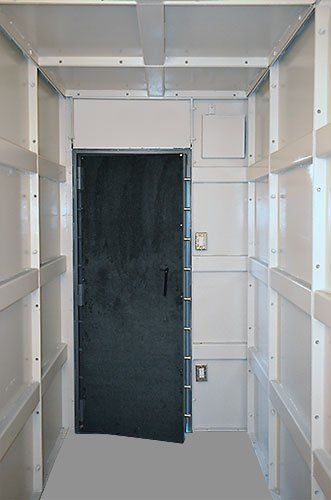

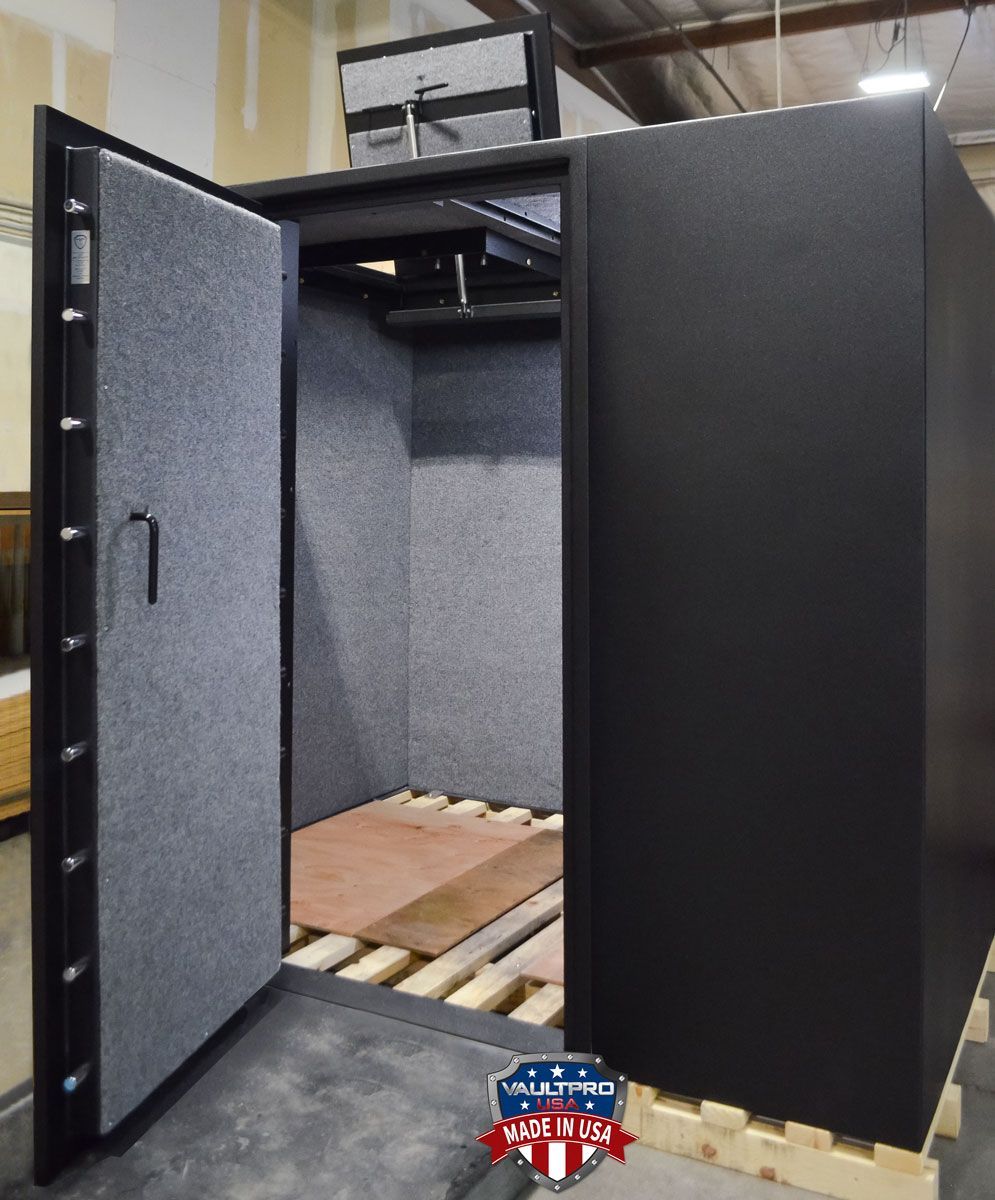

Starting with an approved top down engineered drawing that details the dimensions for each piece and the entirety of your custom walk-in vault…Vault Pro precisely shears each piece of prime grade steel using a 1947 Cincinnati 3/8” x 12’ Shear. After punching all the proper holes along each edge of the steel panel, Vault Pro brakes/bends the proper bolt together flanges on a Cincinnati Press Brake so that front and back of each panel as well as the bolt holes all line up perfectly for easy assembly. After reinforcement channel, bases and tops are welded in, the walk-in vault is assembled to ensure proper alignment of panels and too rough in electrical conduit, and boxes that will ultimately include decorator switches & electrical outlets, stainless steel adorned lighting, stainless steel cover plates and all the applicable wiring and hardware needed to complete your electrical requirements.

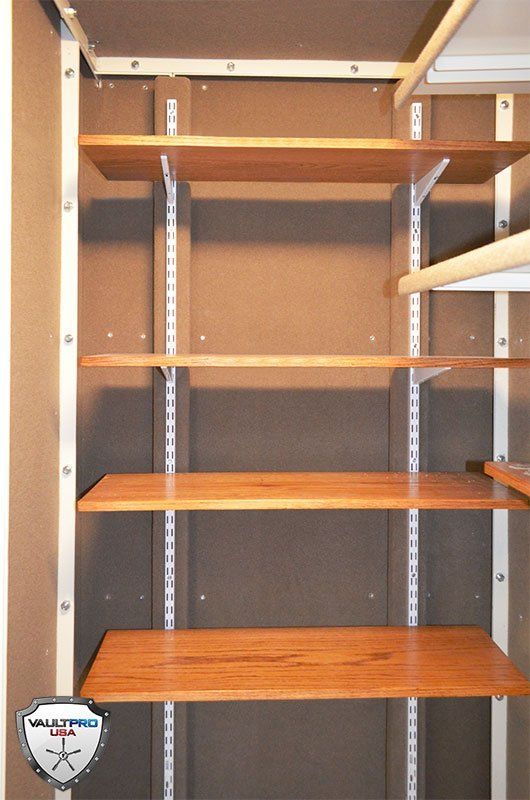

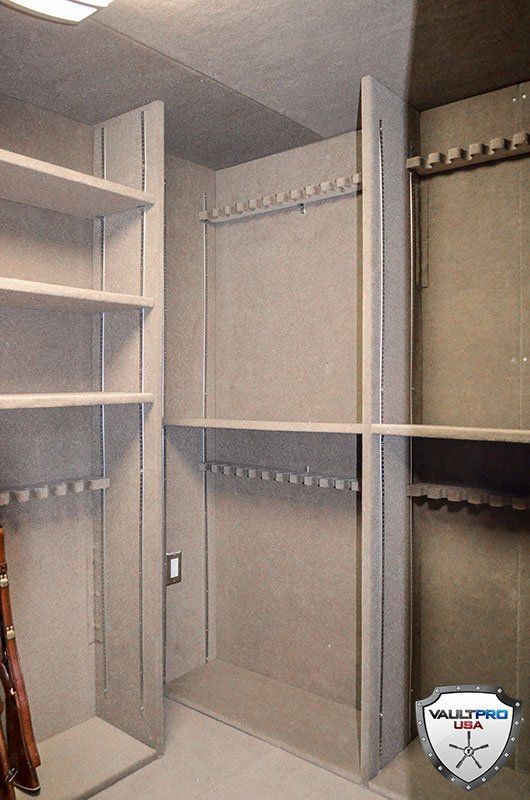

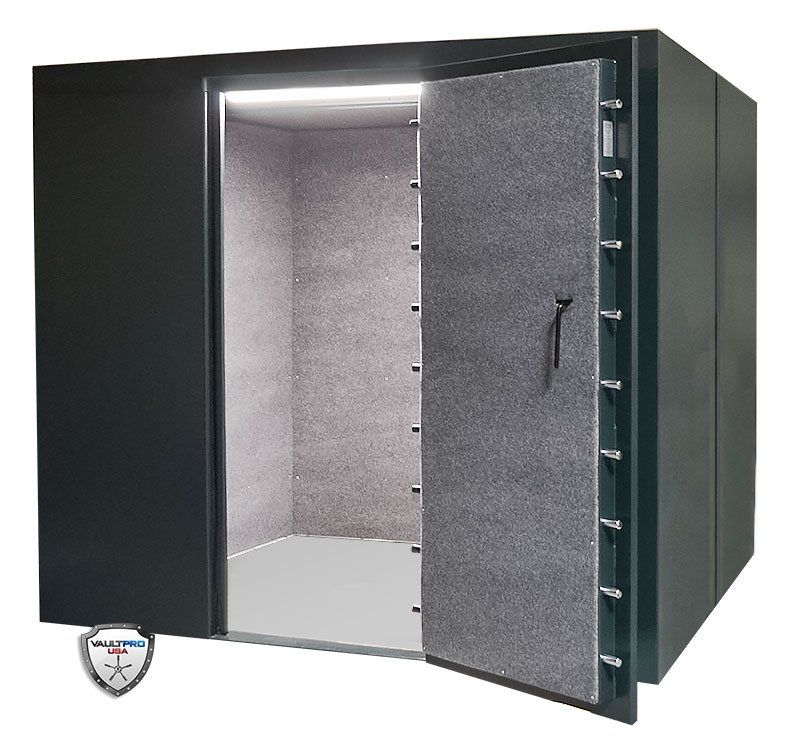

Safe room and Storm Shelter manufacturingHeat and fire resistant materials including 2300° Ceramic fire blanket and X-Rate Fireboard are then cut and set aside along with the upholstered panels that will soon make up the walls inside your Vault Pro Custom Walk-in Vault.

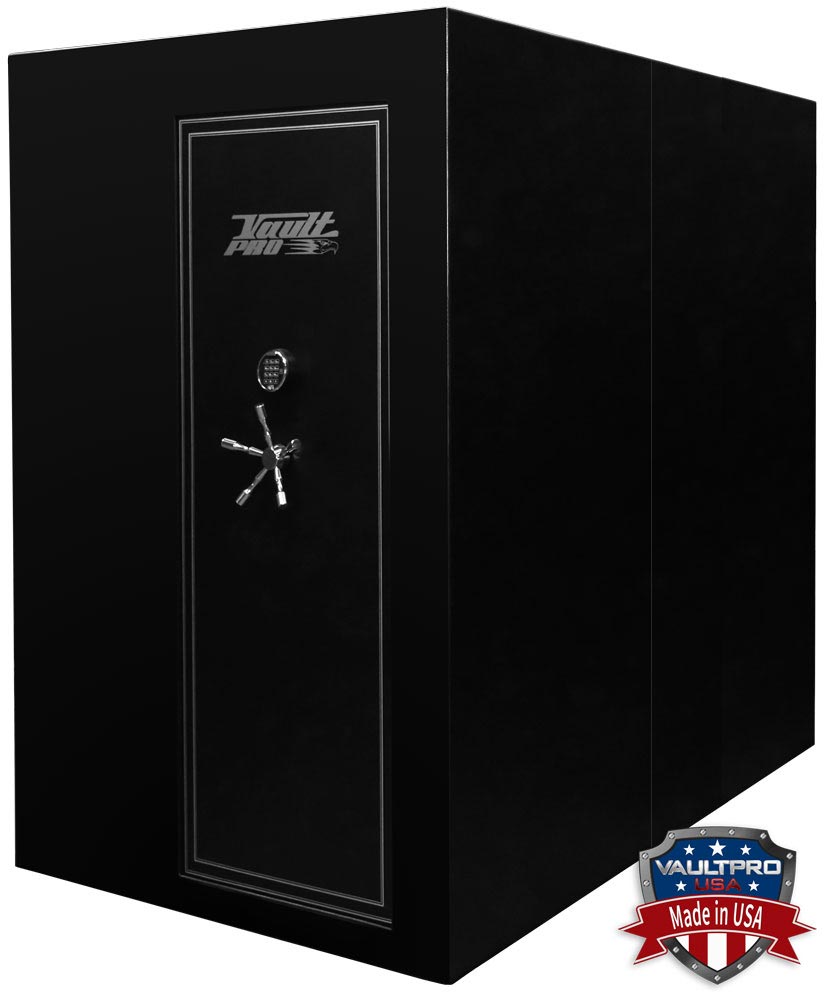

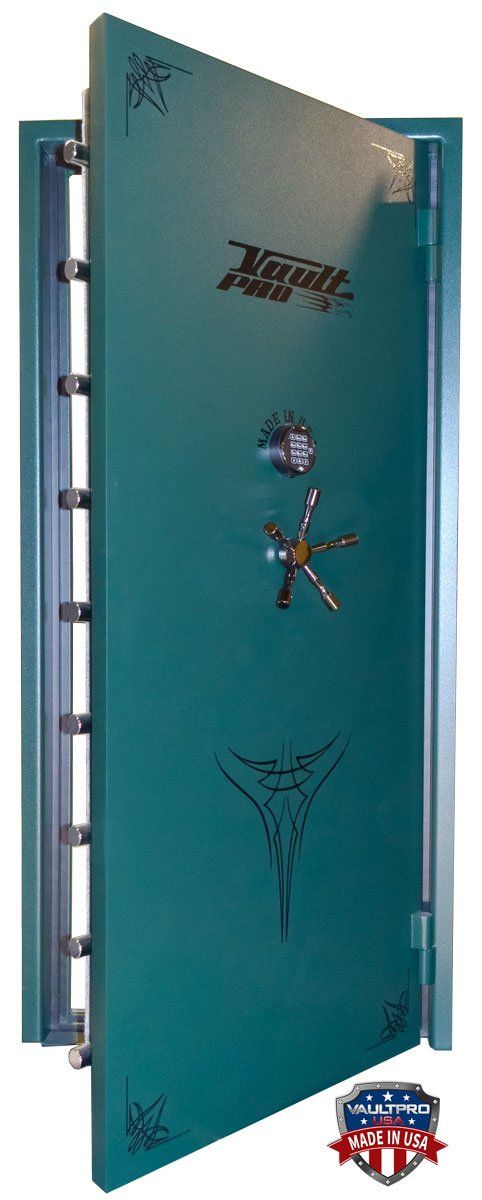

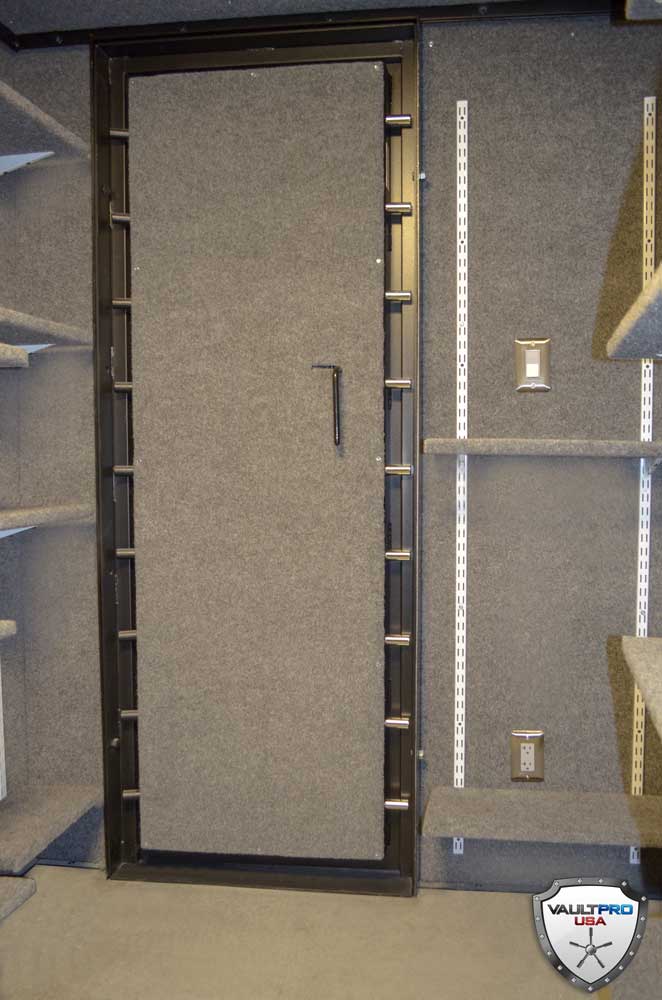

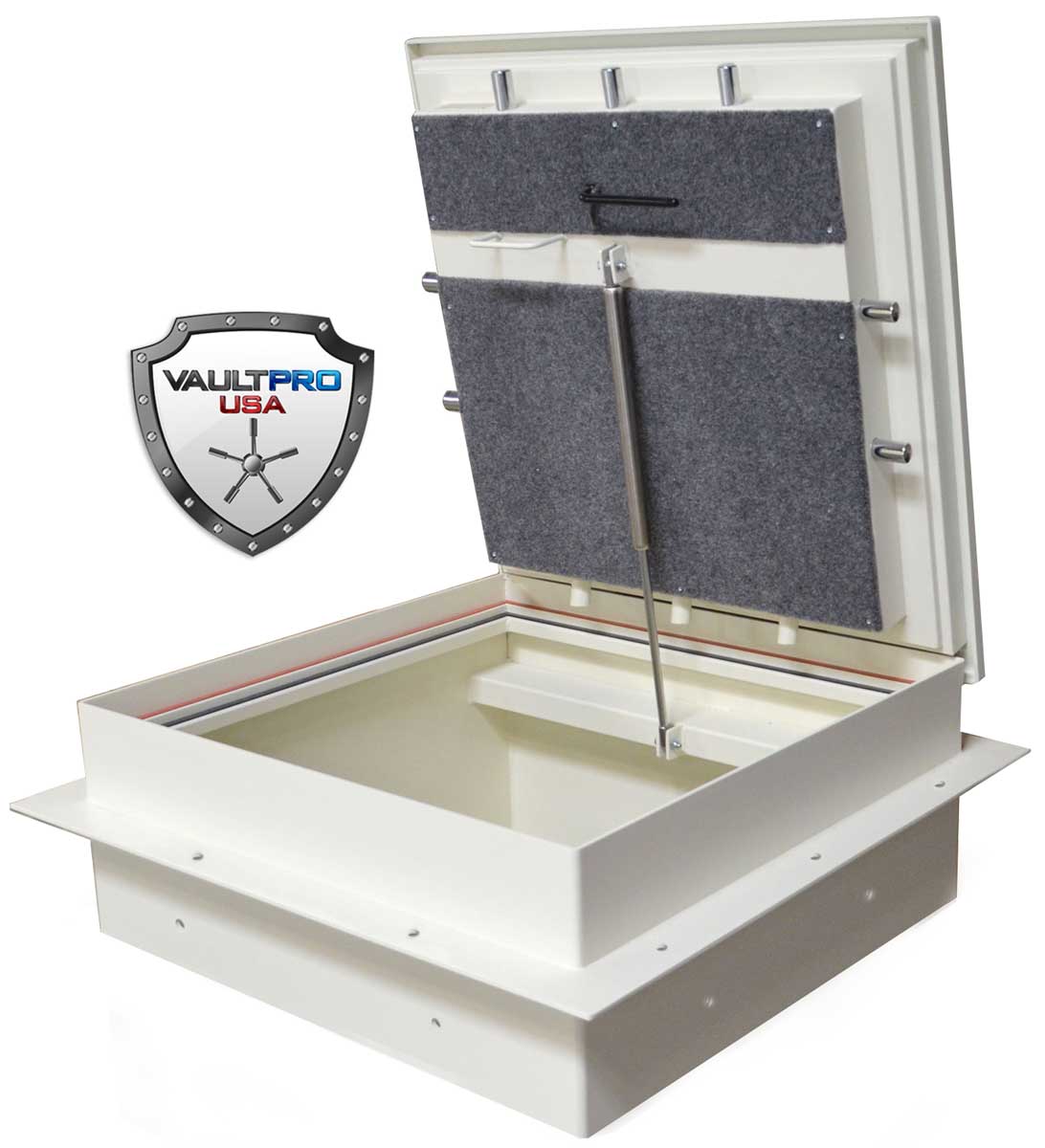

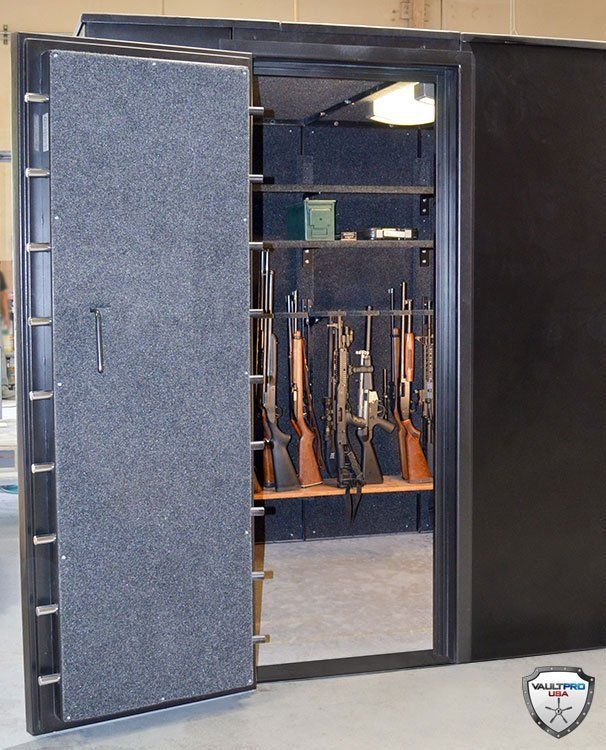

Vault Pro Vault Doors can be In-swinging, Out-swinging, Left Hinged or Right and is custom build to fit the needs and requirements of each client. Vault Pro Vault Doors come in many different steel and overall thicknesses and just as many levels of heat and fire protection. Once built, the door is put in place and perfectly aligned in the vault. A Quality Assurance Inspection is completed for the welding/fitting process, and the entire vault is disassembled.

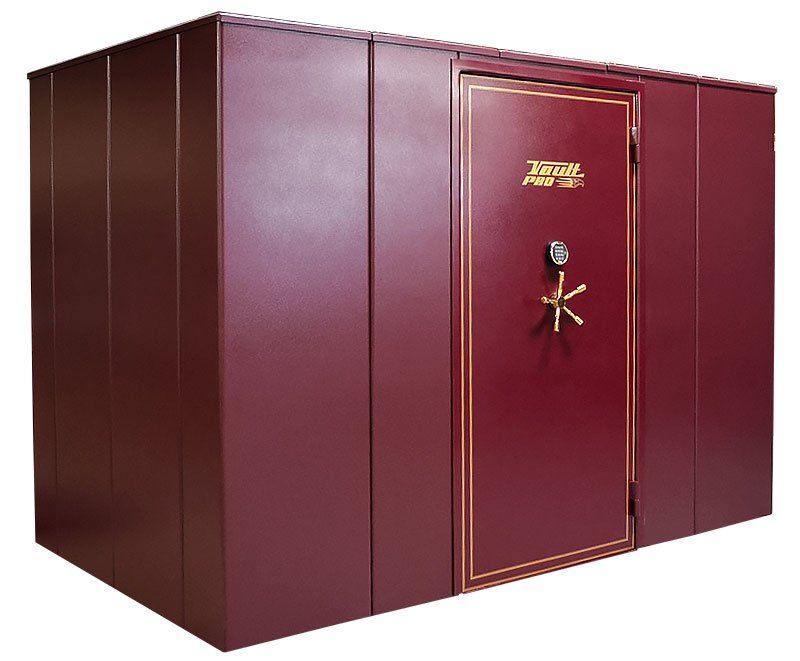

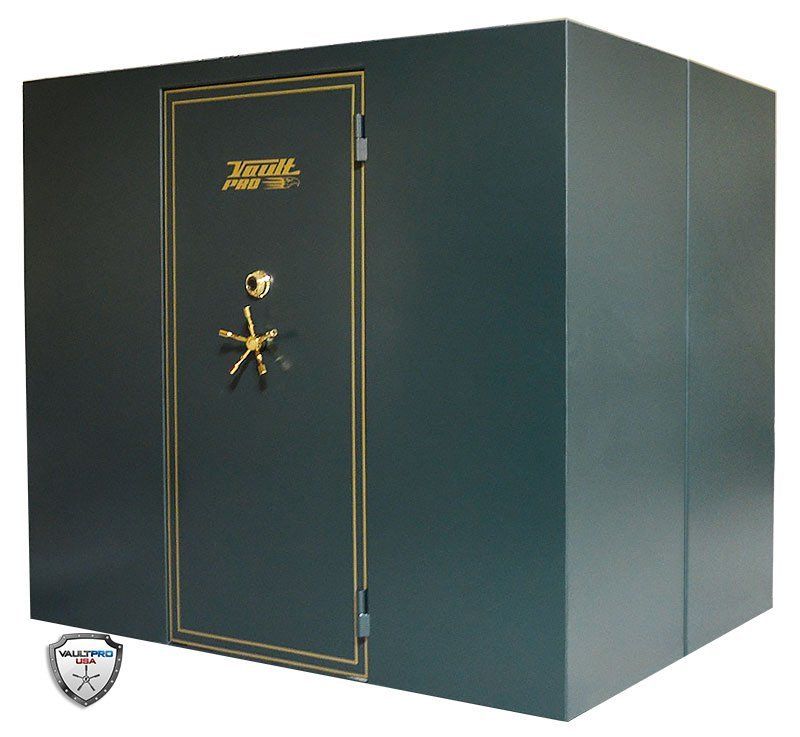

Then it is off to paint, where all of the surfaces of the vault are thoroughly cleaned to remove any wax, grease, oil and welding residues that may remain on the surface of the steel. Simple body work is done and paint is applied to both the interior and the exterior of each piece separately to ensure complete coverage of the steel. Painting also allows for a myriad of color options as well as custom colors to match the aesthetics of any décor.

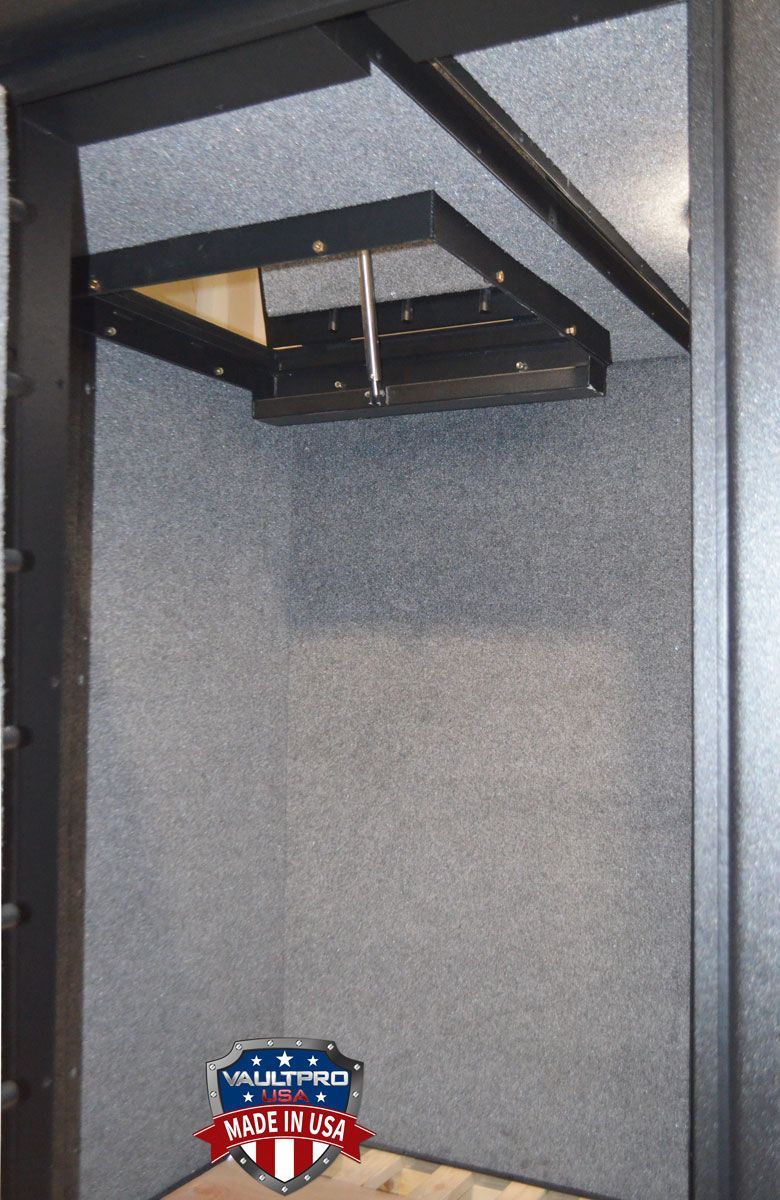

Final assembly requires a great attention to detail as the entire Walk-in Vault is put together completely and thoroughly tested before a final quality assurance inspection is done. A Vault Pro Serialized placard is affixed to the door showing that the door and vault meet the high security and high quality standards Vault Pro is known for.

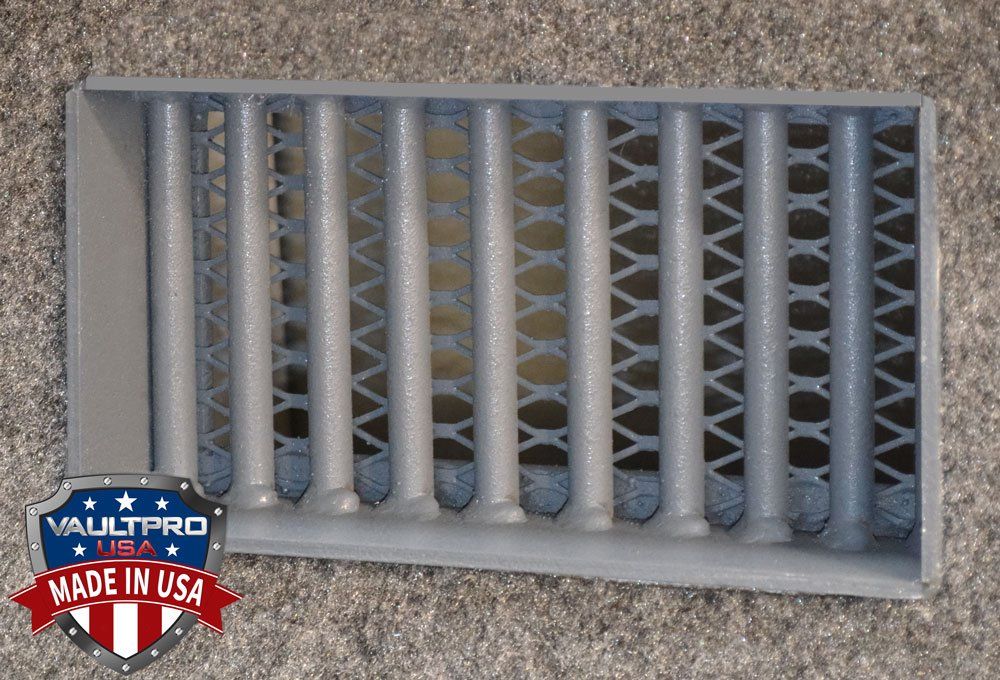

Finally, your Custom Walk-in Vault is disassembled and packaged in reverse order of build so that when it arrives at its final destination is can be easily built starting with the first piece off the pallet being the first piece needed. All of Vault Pro’s Modular products are assembled using ½” diameter, Grade 8 Bolts and Nylock Nuts for the ultimate in strength, durability and ease of assembly.

If for any reason questions or concerns may arise Vault Pro’s World Class Client Service is here to handle any issues.